The Critical Role of Clear and Simple Work Instructions in Electronics Manufacturing

In the fast-paced and intricate world of electronics manufacturing, efficiency, precision, and quality are paramount. At the heart of achieving these goals lies the often underestimated yet critical component: clear and simple work instructions, commonly referred to as Standard Operating Procedures (SOPs). These documents are not mere formalities but essential tools that drive consistency, quality, and safety in every aspect of the manufacturing process.

The Necessity of Clear and Simple Instructions

The electronics manufacturing industry is characterized by complex processes that demand meticulous attention to detail. In this environment, the clarity and simplicity of work instructions are non-negotiable. Ambiguous or overly complex instructions can lead to misinterpretation, resulting in errors, rework, and potentially costly delays.

Clarity and Ease of Understanding

- Eliminate Ambiguity: Work instructions should be written in clear, simple language that leaves no room for misinterpretation. Avoid jargon and complex terms that might confuse workers. Every step should be explicit, precise, and easy to follow.

- Consistency in Quality: Clear instructions ensure that every worker follows the same steps, resulting in consistent quality across all products. This uniformity is crucial in maintaining the high standards required in electronics manufacturing.

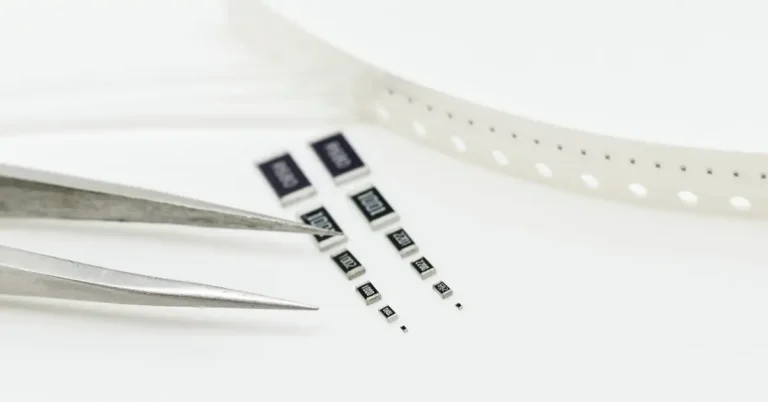

The Power of Visual Aids

- Enhanced Comprehension: Incorporating diagrams, photographs, and videos can significantly enhance the understanding of written instructions. Visual aids provide a reference that can help workers visualize the task at hand, reducing the likelihood of errors.

- Universal Understanding: Visual elements can transcend language barriers, making instructions accessible to a diverse workforce.

Step-by-Step Guidance

- Sequential Steps: Breaking down tasks into sequential, numbered steps makes instructions easier to follow and reduces the risk of missing critical steps.

- Focused Instructions: Each step should be concise and focused on a single task, ensuring that workers are not overwhelmed by information.

Investing Time in Drafting Instructions Pays Off

The time spent on drafting clear and simple work instructions is an investment that pays significant dividends. Here’s why:

Quality and Performance

- Reduced Errors: Well-drafted instructions minimize errors, leading to higher quality products and less rework.

- Increased Efficiency: Workers can perform their tasks more quickly and efficiently when they have clear instructions to follow, boosting overall productivity.

Training and Onboarding

- Faster Onboarding: Clear SOPs allow new employees to quickly get up to speed, reducing the learning curve and minimizing initial errors.

- Consistent Training: Standardized instructions ensure that all employees receive the same training, maintaining consistency across the board.

Safety

- Minimized Risks: Electronics manufacturing involves handling delicate components and dealing with potentially hazardous chemicals and dangerous equipment. For example, pick&place robots, soldering machines, ovens and coating machines. SOPs include safety protocols that protect workers and ensure a safe working environment.

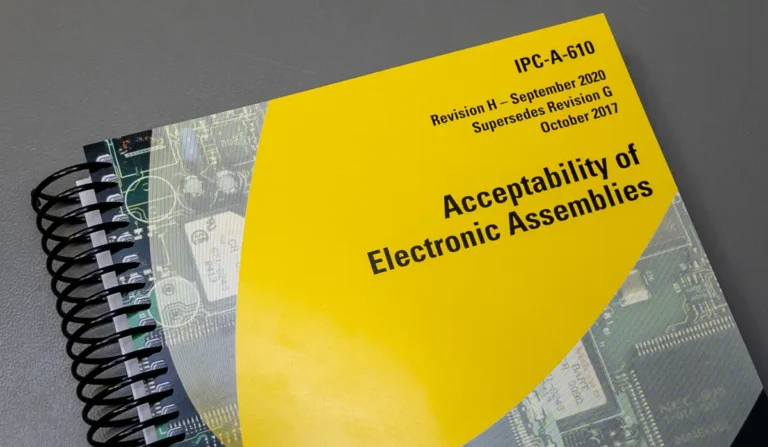

Compliance and Auditing

- Regulatory Compliance: Many industries, including electronics manufacturing, are subject to stringent regulatory standards. Clear SOPs help ensure compliance and facilitate easier auditing processes.

Key Elements of Effective SOPs

- Clarity and Simplicity

- Use straightforward language and avoid unnecessary technical terms.

- Each instruction should be easily understandable by all employees.

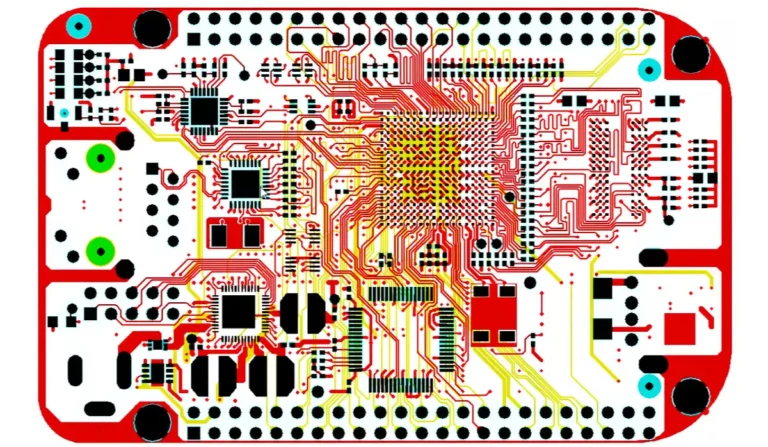

- Visual Aids

- Incorporate diagrams, photographs, and videos to support written instructions.

- Visuals can help bridge language gaps and provide clear examples of expected outcomes.

- Step-by-Step Guidance

- Break down tasks into manageable steps.

- Use numbering and bullet points to enhance readability and flow.

- Accessibility

- Ensure that SOPs are readily accessible to all employees, whether in digital format or printed manuals.

- Consider placing copies at workstations for quick reference.

- Regular Updates

- SOPs should be reviewed and updated regularly to reflect any changes in procedures or technology.

- Engage employees in the review process to gather feedback and continuously improve the instructions.

Overcoming Challenges

Creating effective SOPs is not without its challenges. However, these can be mitigated with thoughtful approaches:

- Complexity of Processes

- Solution: Simplify wherever possible and provide additional training or support for more complex tasks.

- Language Barriers

- Solution: Translate SOPs into multiple languages if necessary and use universally understood symbols and icons. To break down the language barrier, use lots of visuals; pictures, videos, drawings, colour codes, symbols, etc.

- Resistance to Change

- Solution: Involve employees in the development and updating of SOPs to foster a sense of ownership and acceptance.

Conclusion

In the electronics manufacturing industry, the importance of clear and simple work instructions cannot be overstated. SOPs are the foundation upon which consistency, quality, safety, and efficiency are built. By investing time and resources into creating and maintaining effective SOPs, manufacturers can ensure smoother operations, higher quality products, and a safer workplace.

The clarity and simplicity of these instructions are not just best practices; they are essential for the success and sustainability of manufacturing processes. The time spent in drafting these documents is quickly recouped in the enhanced quality and performance of the work, ultimately leading to a more efficient and productive manufacturing environment.