Increasing the Productivity of an SMT Assembly Line

In this article, we compare three different methods to increase the output of an SMT (Surface Mount Technology) assembly line. In our example, the current line speed is around 15,000 components per hour. The tables provided illustrate the impact of changes on the output of the SMT line.

Understanding Uptime

Uptime refers to the actual time during which the SMT line is placing components on PCBs (Printed Circuit Boards). Uptime does not include any stoppages, such as changeovers, component shortages, machine breakdowns, etc. Uptime is measured as a proportion of the total working hours of the line. For instance, if a company operates with two 8-hour shifts and the SMT line places components for 4 hours during these shifts, uptime is calculated as 4h / (8h + 8h) = 0.25 or 25%. For more information, check out my blog article about uptime and downtime.

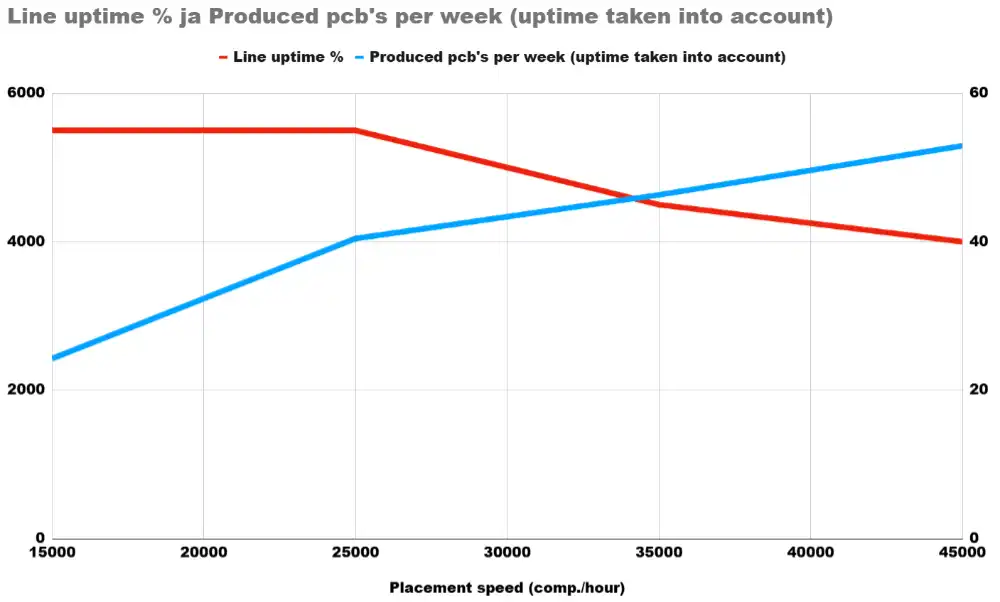

Method 1: Increase Output by Upgrading Equipment

Upgrading to faster machinery will reduce the cycle time per board, increasing the output rate. However, it’s important to consider that if the speed increases significantly, downtime may also increase unless logistical and auxiliary operations, such as component picking and staging, can keep up with the faster pace. Another factor is that the number of changeovers may increase if production batches remain small. It is also essential to ensure that processes following the SMT assembly, such as manual assembly or inspection, are able to handle the increased speed without creating bottlenecks.

Key Points:

- Faster machines can reduce per-board cycle time.

- Auxiliary tasks and logistics must scale with speed to avoid idle time.

- Post-SMT processes must also accommodate the increased output.

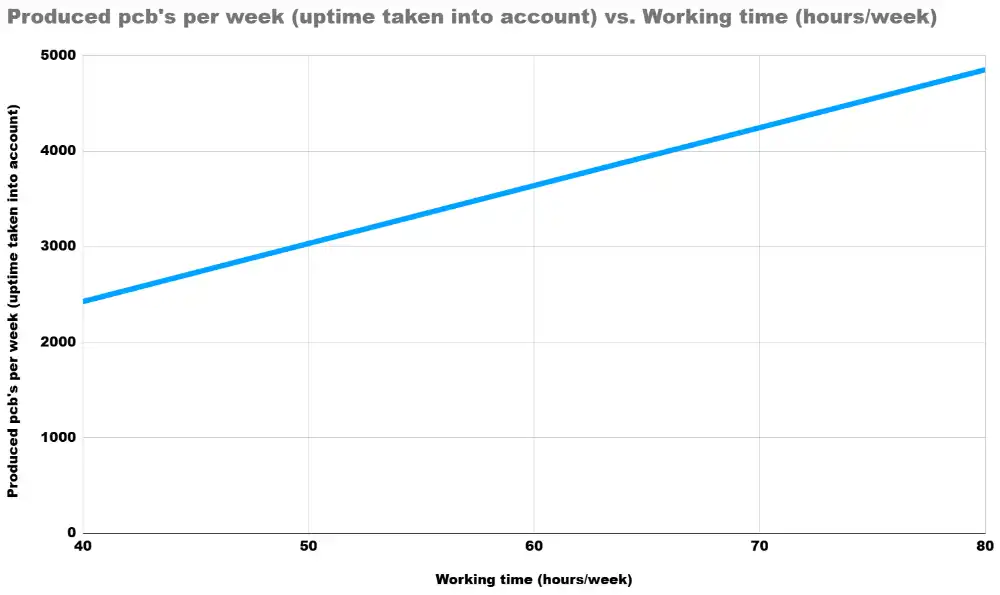

Method 2: Increase Output by Extending Line Operating Time

Another approach to increase production is to extend the operating hours of the SMT line. However, this strategy does not reduce the cycle time per board. To successfully extend the working time, the line will need additional personnel or shift adjustments. If the workforce remains adequate, uptime will remain steady or only decrease slightly.

Key Points:

- Increasing working hours increases production but does not reduce per-board cycle time.

- Adequate staffing is essential to maintain uptime during extended hours.

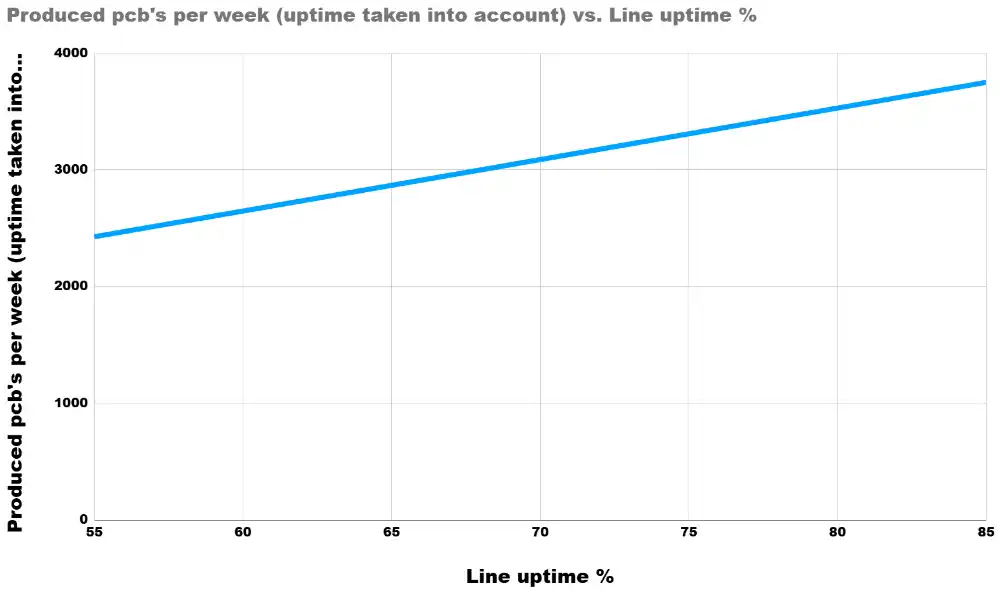

Method 3: Increase Output by Maximizing Uptime

Improving uptime does not directly affect the speed of the SMT line but can still significantly boost productivity. Achieving higher uptime requires good planning and coordination of auxiliary operations. For instance, reducing the time spent on changeovers, running larger batch sizes, and minimizing maintenance and breakdown periods are all ways to keep the line running more consistently. Maximizing uptime is especially beneficial for fast SMT lines, where every minute of downtime results in larger production losses.

Key Points:

- Uptime improvements focus on minimizing downtime rather than speeding up the machine.

- Strategies include optimizing changeovers, running larger batches, and reducing maintenance times.

- This method is particularly impactful for fast SMT lines.