Handling of Moisture-Sensitive Components

Why moisture is harmful to components

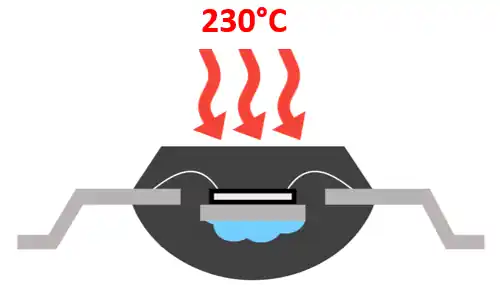

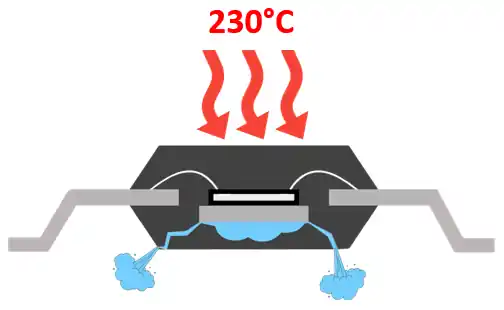

Components absorb moisture from the environment, much like potato chips in an open bag. This becomes problematic when the moisture-laden components are placed on a circuit board and soldered in a reflow oven. The rapid temperature rise above 200°C during the soldering process causes the moisture inside the component to evaporate. This evaporation creates pressure inside the component, which can break the plastic casing or the functional internal part of the component.

What does “MSL” mean?

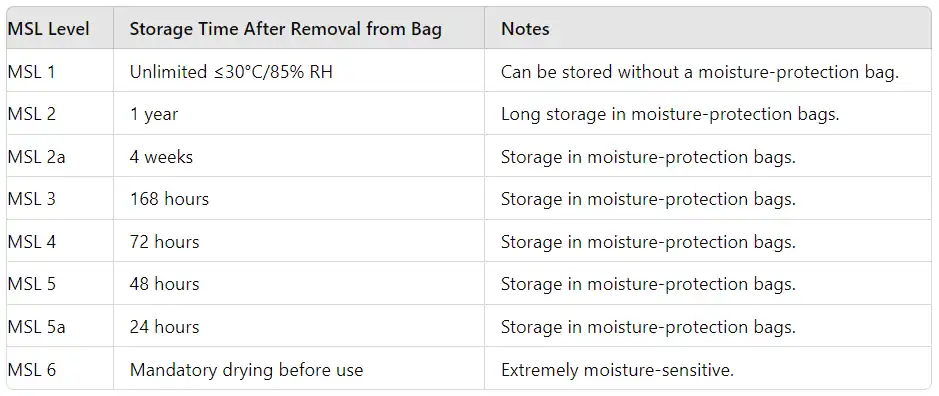

MSL stands for “Moisture Sensitivity Level.” The MSL level determines the time (known as “floor life”) that a component can remain in an opened moisture-protection bag without needing to be dried. Floor life refers to the storage time in an opened moisture-protection bag in a typical factory environment at ≤30°C and 85% relative humidity.

MSL Levels

According to the IPC/JEDEC J-STD-033 standard, there are eight MSL levels:

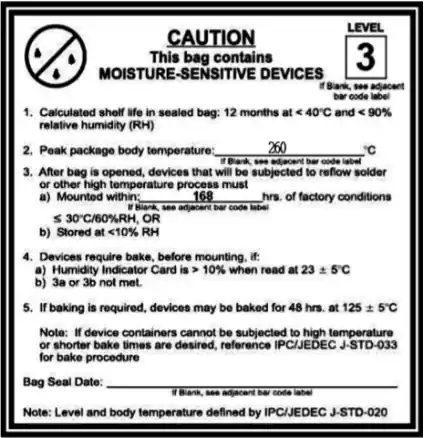

Marking MSL Levels on Moisture-Protection Bags

The MSL levels marked on component packaging vary depending on the manufacturer. Sometimes the marking is clear, and other times it can be hard to find. If no marking is present on the package and there is suspicion that the component is moisture-sensitive, the MSL level should be verified with the manufacturer.

Typical MSL Levels for Components

MSL 1:

Passive components such as resistors, capacitors, diodes, connectors, and other mechanical components.

MSL 1:

Transistors, FETs, regulators, etc.

MSL 1-6:

Logic circuits, memory chips, data converters, sensor ICs, etc. Some high-power LEDs as well.

Closing a Moisture-Protection Bag

A moisture-sensitive component’s moisture-protection bag should always be sealed watertight with a heat sealer. If you need to open the moisture-protection bag, reseal it immediately after use with a heat sealer. For components rated MSL 2-6, a desiccant bag and a moisture indicator should be included inside the moisture-protection bag. Vacuum sealing is not required but can be used if the goal is to make the packaging smaller and more stable.

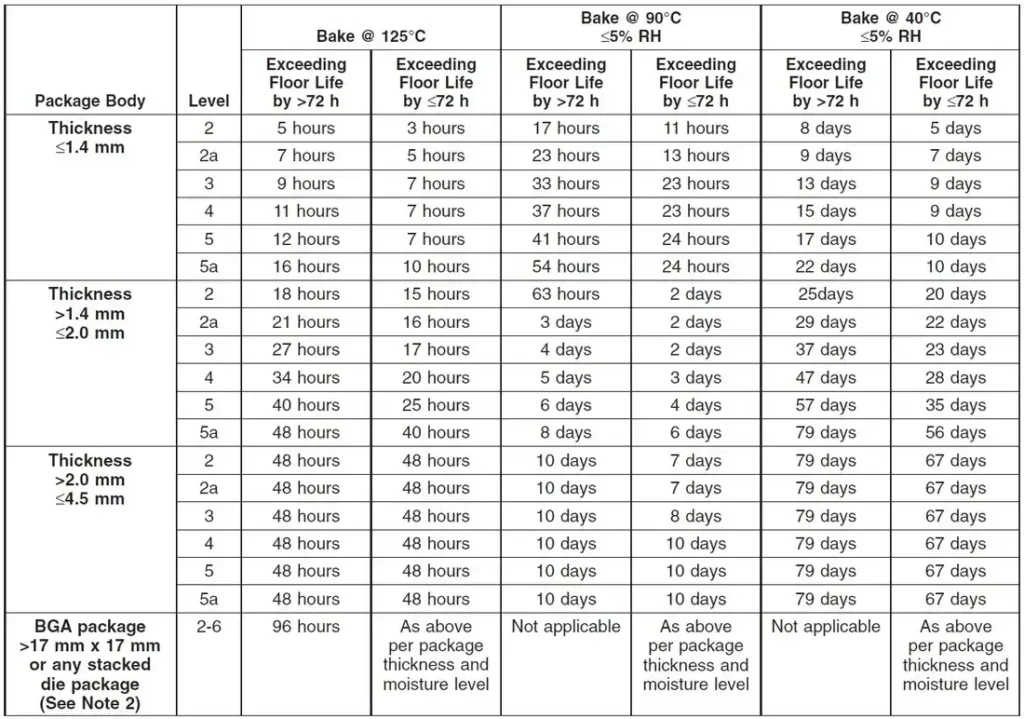

Drying Components

A moisture-sensitive component must be dried before placing it on a circuit board if the storage time in an opened moisture-protection bag is exceeded. The drying time depends on the component’s MSL level, thickness, and drying temperature. When selecting a drying temperature, the heat resistance of the component’s packaging must be considered. For example, a component in a plastic package cannot be dried at 125°C if the packaging or reel melts at a lower temperature. A table based on the IPC/JEDEC J-STD-033 standard that lists drying times is shown below.