Benefits of Vapor Phase Soldering with the Asscon VP800

Vapor phase soldering is a game-changer for electronics manufacturing, and the Asscon VP800 brings some impressive benefits to the table. Here’s why you should consider it:

- Oxidation-Free Process: Soldering in an oxygen-free environment ensures cleaner joints.

- Stable Soldering Temperature: Unlike traditional reflow soldering, vapor phase offers a lower and consistently controlled temperature.

- No Overheating: There’s no risk of overheating components, making it safer for delicate parts.

- Uniform Heating: Regardless of the shape, mass, or color of the components, the heating is even.

- Superior Penetration: The hot vapor, with its low surface tension, gets into the tiniest gaps, perfect for BGA’s and similar fine pitch components.

- Repeatable Profiles: You get a consistent solder profile every time without needing adjustments for different boards.

How It Works

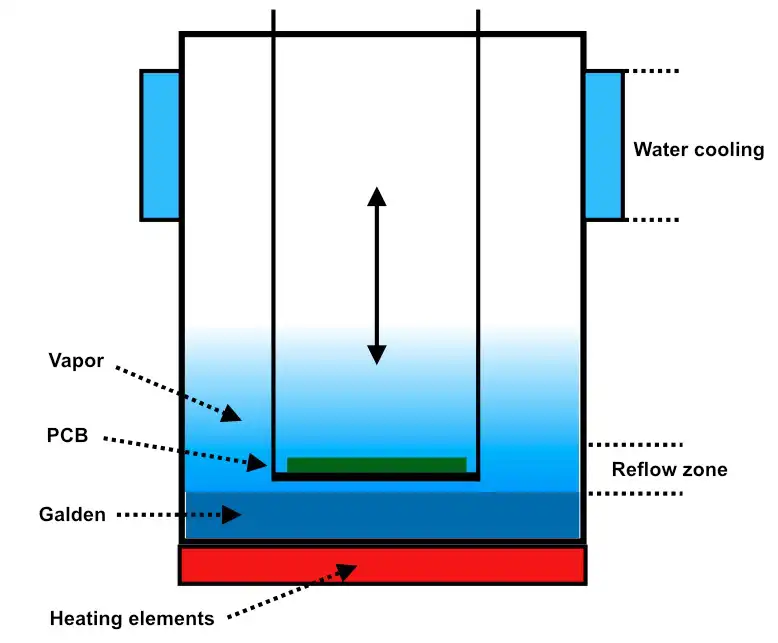

The Asscon VP800 is a semi-automatic machine, designed for efficiency and precision. Here’s a simplified look at its operation:

- Setup: Place the circuit board in the lift and manually start the soldering program.

- Automatic Process: The soldering process itself is fully automated.

- Heat Transfer Medium: It uses Galden LS230 fluid, boiling at 230°C, ensuring the maximum soldering temperature is the same.

Different Soldering Types

- Lead Soldering:

- LS200: 200°C boiling point

- LS215: 215°C boiling point

- Lead-Free Soldering:

- LS230: 230°C boiling point

- HS240: 240°C boiling point

Choosing the Right Heat Transfer Fluid

A crucial tip is to select a fluid with a boiling point 10-12°C higher than the solder paste’s melting point. For example, SAC305 solder paste melts at 217°C, so you should use a fluid with at least a 227-229°C boiling point.

The Soldering Process

The process is straightforward:

- The circuit board moves down into the soldering chamber and back up again.

- At the bottom, the Galden fluid heats to its boiling point.

- The vapor above the fluid, at the same temperature, heats the board and solder paste.

Soldering Parameters

Parameters are split into preheating and reflow soldering. While you can theoretically tweak these by changing times and distances, the key parameter in the Asscon VP800 is the heating power during reflow soldering:

- Heating Power: The more power to the heating elements, the faster the hot vapor forms to heat the board.

- Profile Length: For a recommended soldering profile of 300 seconds, set the heating power to around 55%.

- Consistent Temperature: Once the board is in the reflow zone, it heats uniformly to 230°C, without exceeding this temperature.

Why Choose Asscon VP800?

The Asscon VP800 offers a streamlined, reliable, and precise soldering solution, minimizing risks and maximizing efficiency. Whether you’re dealing with complex circuit boards or simple designs, this machine ensures top-notch quality every time.

Using vapor phase soldering not only enhances the quality of your solder joints but also simplifies the process, making it a must-have for modern electronics manufacturing. The Asscon VP800 combines cutting-edge technology with user-friendly operation, ensuring you get the best results with minimal hassle.