The Art and Science of Hand Soldering

Welcome to the fascinating world of hand soldering, an essential skill for anyone involved in electronics. Whether you’re a hobbyist or a professional, mastering hand soldering can significantly improve the quality and reliability of your electronic devices. This guide will walk you through the basics, ensuring you understand every step of the process.

What is Soldering?

Soldering involves joining two metals using a filler material called solder, creating a solid electrical and mechanical bond. The key elements of soldering are:

- Heat: Provided by a soldering iron.

- Solder: A mixture of metals that melts to form the joint.

- Flux: A chemical agent that cleans and prepares the metal surfaces.

The Essentials of Solder

Solder typically consists of a mix of metals with varying properties. For example, a common lead-free solder is Sn95.5/Ag3.8/Cu0.7, which means it contains 95.5% tin, 3.8% silver, and 0.7% copper. This mixture melts at around 217°C. Other popular compositions include Sn96.5/Ag3.0/Cu0.5 and Sn99.3/Cu0.7, each with its specific melting points and characteristics.

The Role of Flux

Flux is crucial in the soldering process, performing several functions:

- Cleans oxidation from metal surfaces.

- Prevents re-oxidation during soldering.

- Reduces surface tension of the solder.

- Helps heat transfer from the soldering iron to the components.

Flux types are categorized based on their composition and activity levels, such as Rosin (RO), Resin (RE), Organic (OR), and Inorganic (IN). Each type is suited for different applications, with varying levels of activity and halide content.

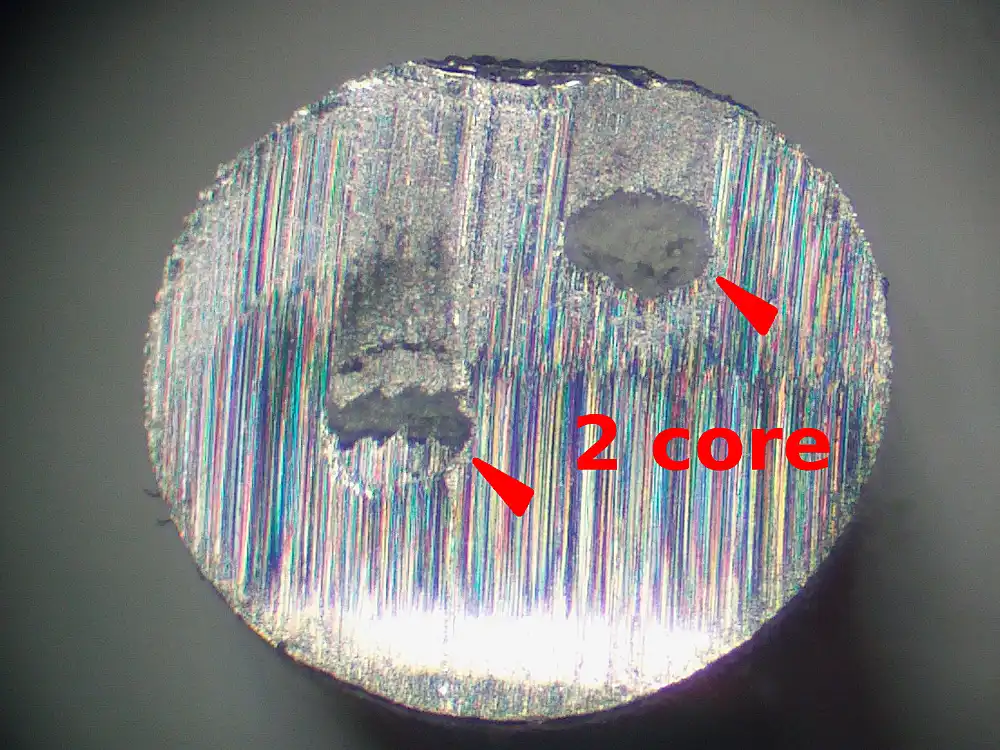

Choosing the Right Solder Wire

Solder wire comes in various types, each suited for different applications. Important factors to consider include:

- Alloy Composition: Determines melting point and joint strength.

- Flux Type and Content: Affects how well the solder flows and bonds.

- Wire Diameter: Impacts ease of use for different sized components.

Handling and Using Solder Wire

Always handle solder wire with care. Use gloves to avoid flux residues on your hands and cut the wire with side cutters to prevent damaging the flux core. Proper storage ensures the flux remains effective for a long time.

The Soldering Station

Your soldering station is the tool that brings everything together. Modern soldering stations allow precise temperature control, essential for achieving consistent, high-quality joints. High-end models may feature fixed-temperature tips, which are calibrated for specific tasks. Personally, I recommend a soldering station with adjustable temperature control.

Choosing the Right Soldering Tip

The right tip makes all the difference. Larger tips transfer heat more efficiently but may not fit into tight spaces. Always use the largest tip that fits your work area to maintain optimal heat transfer.

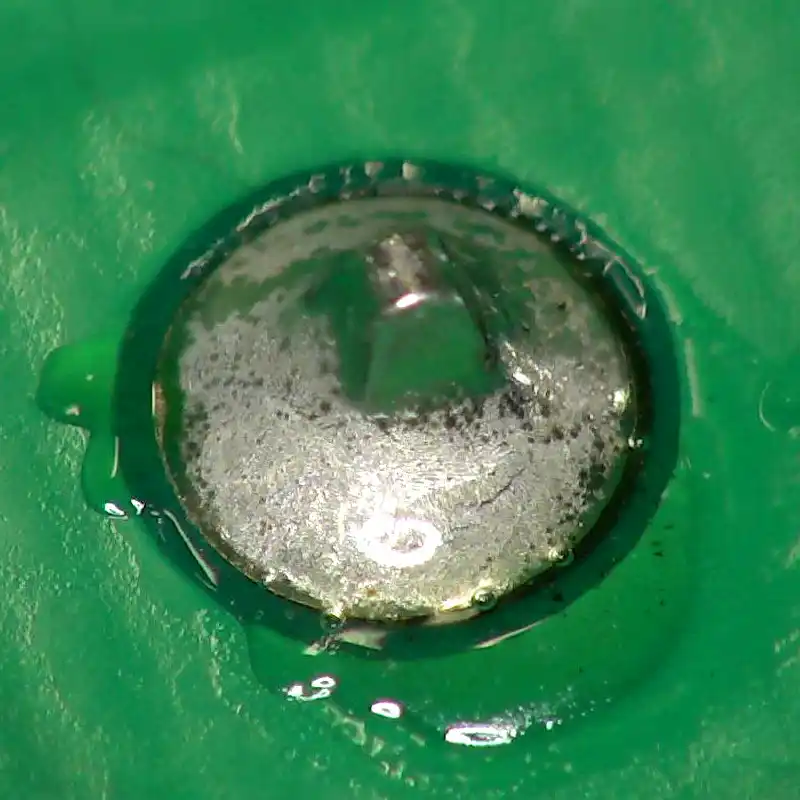

The Soldering Process

Let’s break down the soldering process into four simple steps:

- Preheating: Lightly press the soldering iron to the joint to preheat it (2-3 seconds).

- Applying Solder: Feed the solder wire into the joint slowly, allowing it to melt and flow (2-5 seconds).

- Heating: Keep the soldering iron in the soldering and let it heat up (1-2 seconds).

- Cooling: Remove the iron and let the joint cool undisturbed.

Each solder joint should take about 5-10 seconds. If it takes longer, check your iron’s temperature, tip size, and consider preheating the board with an auxiliary bottom side preheater.

Safety First

Soldering involves high temperatures and potentially hazardous fumes. Always work in a well-ventilated area, use protective gear like gloves and safety glasses, and ensure effective fume extraction.

Further Reading and Resources

For those serious about honing their soldering skills, delve into the IPC-A-610 standard, which offers detailed guidelines and quality standards for electronic assemblies. Though it is a paid resource, it is invaluable for professional work.